Electrolytic coloring, also known as electrolytic processing, is a metal surface treatment process that can make the metal surface have a more beautiful and durable surface color.

Electrolytic processing can be divided into two types: non-corrosive processing and corrosive processing. Non-corrosive processing will not damage the metal surface, but only electrolyze the metal surface to a specific color, while corrosive processing will corrode the original structure of the metal surface and replace the original color with a specific color of the metal.

Generally speaking, electrolytic machining can be divided into three steps:

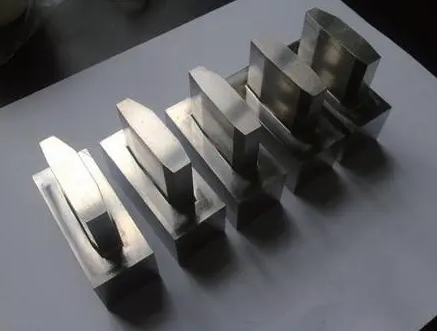

- Electrodeposition: Selected electrodeposition is carried out at the designated position of the metal surface to obtain a specific surface morphology and color.

- Heating treatment: Heating treatment is to fix the color of the electro-deposition on the metal surface to achieve a more beautiful and durable color effect.

- Polishing: Polishing the metal surface into a smooth surface to enhance the gloss and beauty of the surface.

With electrolytic machining, the metal surface can be made into different colors according to needs, such as black, golden yellow, gray, etc., to obtain a more beautiful effect. In addition, electrolytic machining can also be used for the surface treatment of castings to achieve wear resistance, corrosion resistance and other effects.

Electrolytic machining technology has a wide range of applications in industrial production. It can improve the appearance of products, increase the durability of products, enhance the use value of products, and improve the appearance quality of products.

The development of electrolytic machining technology has greatly improved metal surface treatment technology and greatly improved the appearance and performance of metal surfaces. The emergence of electrolytic processing technology has brought metal surface treatment technology to a new level, making it more reliable, more beautiful and more durable, thus bringing more possibilities for metal surface treatment.