Product Introduction

Electroplating is a process of surface processing of parts by electrolysis. During electroplating, the parts are anodes, and the metal ions in the plating solution are deposited on the surface of the parts under the action of direct current to form a uniform and dense metal coating. The electroplating process equipment is the production process carried out by the electroplating workshop, which can be divided into three links, namely, pre-plating surface treatment, electroplating treatment and post-plating treatment. Electroplating process equipment generally refers to the above-mentioned production equipment that directly processes parts. The main processes of pre-plating surface treatment include polishing, brushing, rolling, sandblasting, degreasing, derusting, corrosion, neutralization and cleaning.

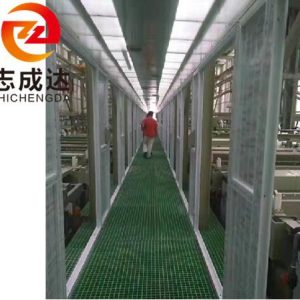

The equipment used in the electroplating process mainly includes various fixed tanks, rolling plating tanks, hangers, hanging baskets, etc. Post-plating treatment is to polish, lighten, passivate, color, dry, seal, dehydrogenate and other work on the parts. The gantry-type hanging plating production line selects one or several processes according to the needs to make the parts meet the quality requirements. The commonly used equipment for post-plating treatment mainly includes grinding, polishing machines, and various fixed tanks.

Product parameters

1. There should be good bonding between the coating and the base metal, and between the coatings.

2. The coating should be finely crystallized, flat and uniform in thickness.

3. The coating should have the specified thickness and as few pores as possible.

4. The coating should have the specified indicators, such as brightness, hardness, conductivity, etc.

5. The ambient temperature is -10℃~60℃;

6. The input voltage is 220V±22V or 380V±38V;

7. The maximum working noise of the water treatment equipment should not exceed 80dB(A).

8. The relative humidity (RH) should not exceed 95%;

9. The COD content of the raw water is 100mg/L~150000mg/L.

10. The electroplating time and the temperature of the electroplating process determine the thickness of the coating.

Reviews

There are no reviews yet.