Medical Device Solutions

Electroplating equipment Important uses of electroplating technology in the medical industry

How electroplating technology optimizes medical devices

Electroplating can be used to improve the functions of various aspects of medical devices. For example, electroplated metals can be used to conduct heat and electricity, provide good wear resistance, corrosion resistance, form strong welds, establish antibacterial and biocompatible surfaces, and make markers and catheter braids that are not transparent to X-rays.

Electroplated metals, such as copper and silver, are two of the best thermally conductive metals. Therefore, they can be added to medical ablation devices to conduct heat, eliminate tissue carbonization and adhesion between tissue and equipment. Because metals are good conductors of electricity, electroplating has historically been used to make components used in electronic devices. Silver, copper, and gold are the most conductive metals. However, due to the high cost of gold, it is rarely used in medical devices. On the other hand, silver of various thicknesses is relatively cheap, and in many cases, silver can reduce parasitic power consumption by 90%, improving the battery life of portable devices. Moreover, due to the high conductivity, the surface of medical devices can be fully or partially conductive with silver and copper. Additionally, during the electroplating process, the geometry of the electrodeposit can be shaped to fit the optimal dimensions, helping to reduce the overall size of the device. Electroplating can be used to improve the wear resistance of the device by adding diamond particles to the nickel coating. Additionally, since implanted devices are subject to the moist environment of the body, the chlorine swabs used to sterilize many medical devices can damage the metal surface, and manufacturers must consider corrosion resistance in the design process. To achieve corrosion resistance, devices can be plated with a variety of materials, including rhodium, gold, palladium, and nickel.

Improving the design process for medical devices

Small mechanical designs can either facilitate or hinder the electroplating process. For example, substituting one electroplated metal for another can significantly reduce costs and improve device performance. By the same token, if something as simple as a cutting path goes wrong, the part will fail during the electroplating stage.

How patients benefit from electroplating

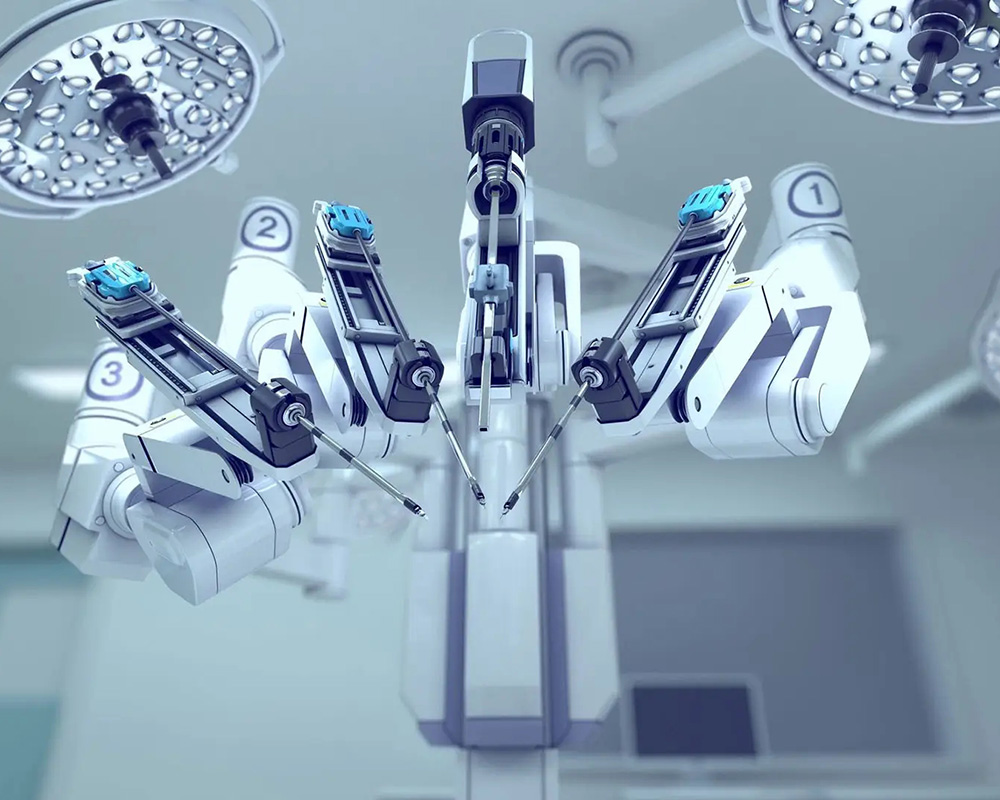

Minimally invasive surgery and the corresponding small surgical instruments are needed to reduce hospital stays and control medical costs. Patients also benefit from minimally invasive surgery because it is less invasive and has a faster recovery. As an additive manufacturing process, electroplating can be used to manufacture tools and instruments used in minimally invasive surgery. For example, electroplated catheters can be used to precisely and quickly position devices such as vascular stents or heart valves. Therefore, electroplating processes can provide many solutions as a valuable design tool to address the challenges facing medical device designers in today’s difficult medical environment.