What are the methods for maintaining and servicing electroplating equipment in PCB factories?

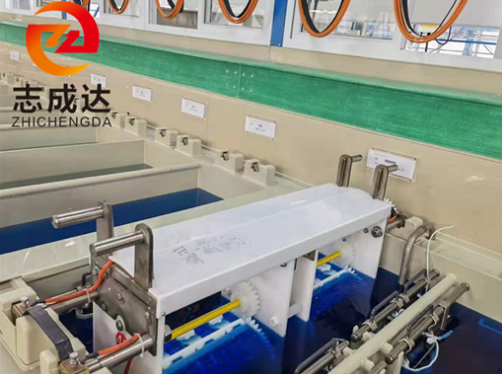

There are two main types of electroplating equipment used by PCB manufacturers: horizontal electroplating line and vertical electroplating line. The two types of electroplating equipment have different structures, different ways of transporting circuit boards, and slightly different maintenance. So, what are the methods for maintaining and servicing electroplating equipment of PCB manufacturers? In vertical electroplating, […]