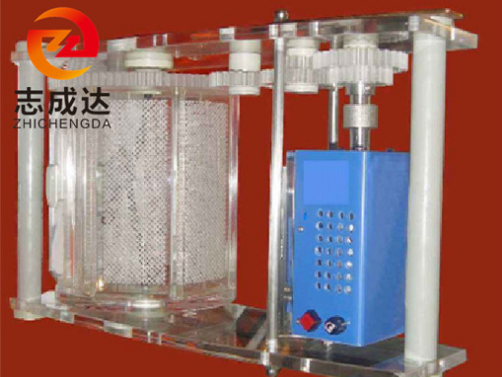

Electroplating equipment can meet the electroplating process of various parts

Each crane of the electroplating equipment manufacturer runs according to the pre-programmed sequence. This production line consists of 32 stations. The automatic control of the crane on the electroplating production line is the key to the automatic control of the electroplating production line. The electroplating production line is completed by 4 cranes according to its […]

Electroplating equipment can meet the electroplating process of various parts Read More »